Key theme ___ Additive Construction Methods

Key theme ___ Additive Construction Methods

What Is Additive Manufacturing in Construction?

Flexibility of form and in the timing of production

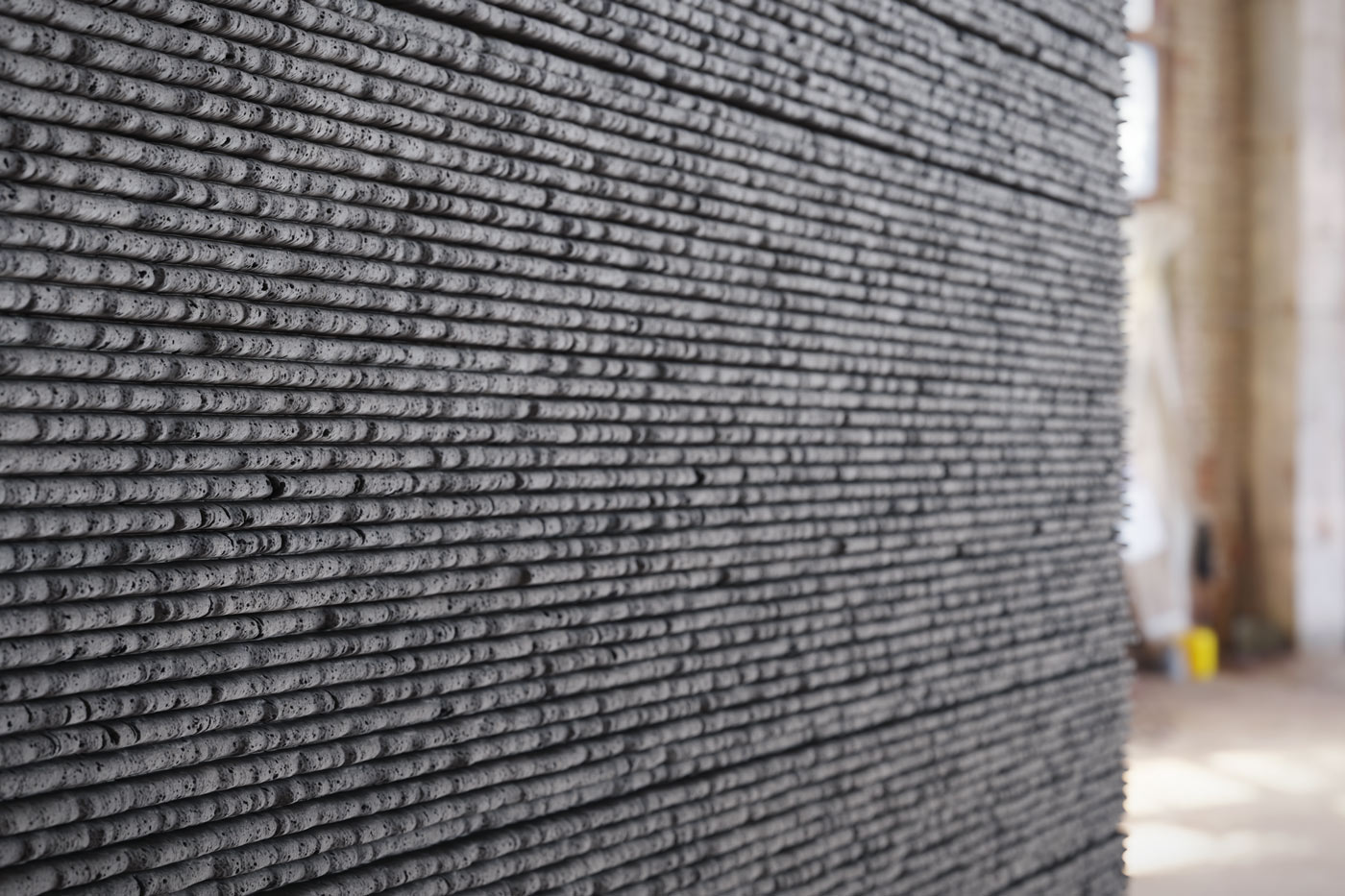

3D printing is a synonym for additive manufacturing, in which a material is built up layer by layer to produce a component. In construction, this means a manipulator moves the print head along a required trajectory, applying the material layer by layer. These layers then create the structure. The material used is typically mortar or concrete.

Transferring 3D printing technology into construction practice more broadly requires an interdisciplinary approach involving construction management, construction machinery and construction materials.

Construction Future Lab offers a large-scale testing ground for investigation of various issues as the technology is further developed.

The real potential of 3D concrete printing

Accelerated construction work and increased labor productivity

Elimination of shuttering and scaffolding

Reduction of construction process to a few key operations

Reduction in technically complex manual work

Work Area ___ 01/03

Development of machine technology: Printhead / sensor technology

The printhead is the tool used to pour concrete. A robust and simple design along with versatile and reliable processing of different materials ensure that the printing process is trouble-free. In addition to the structural design, sensor integration and the closing of control loops are essential. This allows construction projects to be documented during printing and increases the degree of automation.

Robust machine technology, reliable materials processing and appropriate automation solutions provide the basis for transferring 3D concrete printing from the laboratory to practical tasks.

Work Area ___ 02/03

Construction process: The digital process chain

In order to produce a building that has been planned, additive construction processes require a printing strategy. A continuous process chain is needed, from the building model through machine control of the printing process to the digital documentation model, in order to ensure automated construction methods are cost-effective and correctly executed.

One challenge is the automated processing of the data required to control the concrete 3D printer, taking into account the printing material and machine, as there are currently no standards for digital process flows. In addition, the lack of measurement technology makes it difficult to collect data to document the execution phase.

A closed data chain—from planning to execution and back—enables execution quality to be increased and printing scenarios to be reproducible.

Work Area ___ 03/03

Reinforcement integration: Steel reinforcement

To view the live stream, you must functional cookies must be active.

Follow in real time how the CFLab in Görlitz – our test area and testing ecosystem – is taking shape on an area of 80,000m2. The live camera offers you a direct view of the construction site and shows the progress of our project. Completion is planned for 2026.